Business

Energy

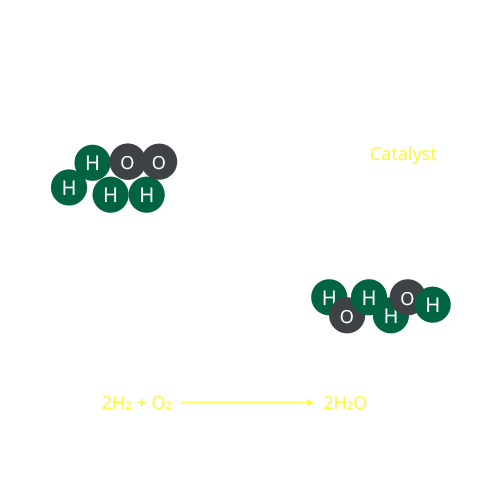

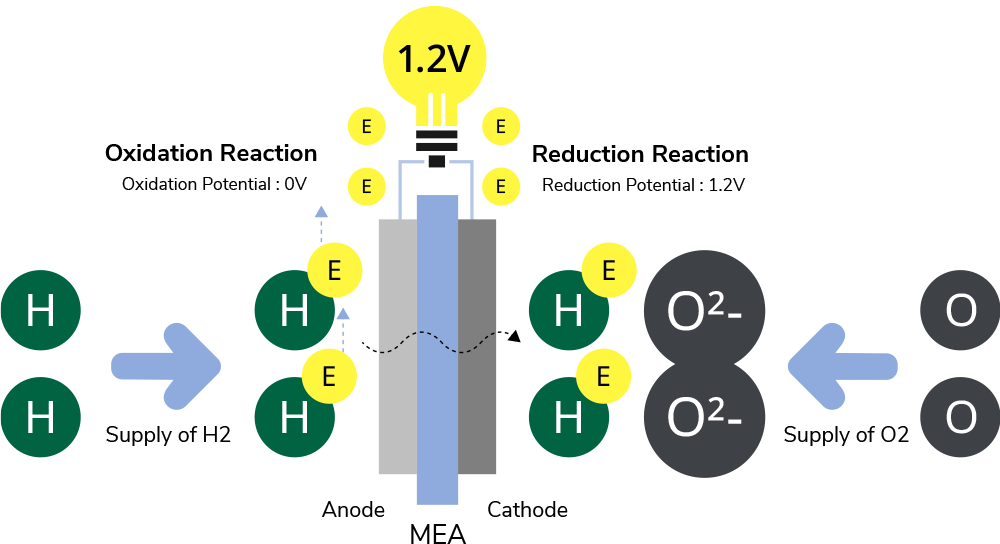

Principle of Fuel Cells

Fuel Cell: Unlimited electricity generation

(electricity is produced through hydrogen supply).

H2

Air Purification

Water Discharge

H2

Air Purification

Water Discharge

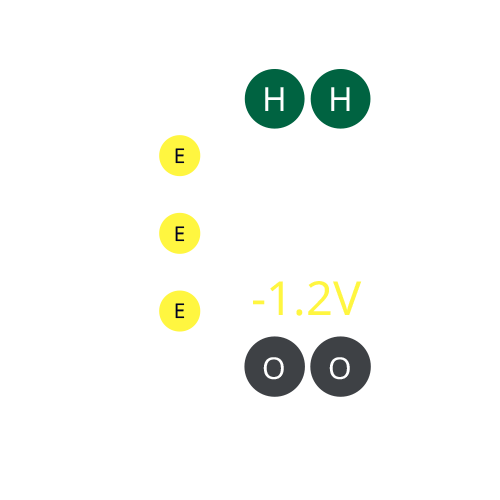

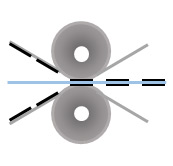

Principle of Electron Flow

Current flow occurs due to the potential difference between oxidation and reduction potential.

Chênh lệch mực nước = chênh lệch điện thế (tạo ra dòng điện tử)

Electron and ion movement occurs by causing oxidation and reduction reactions at the electrode due to the potential difference.

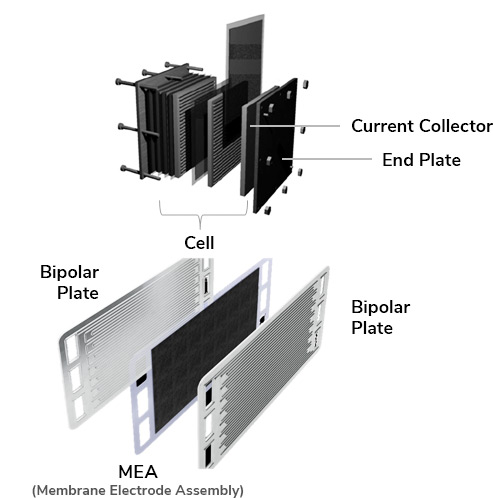

Fuel Cell Core Components

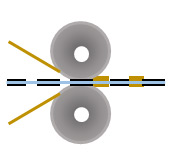

Fuel Cell Stack Structure

MEA stacked in the form of cells by combining with the separator plate.

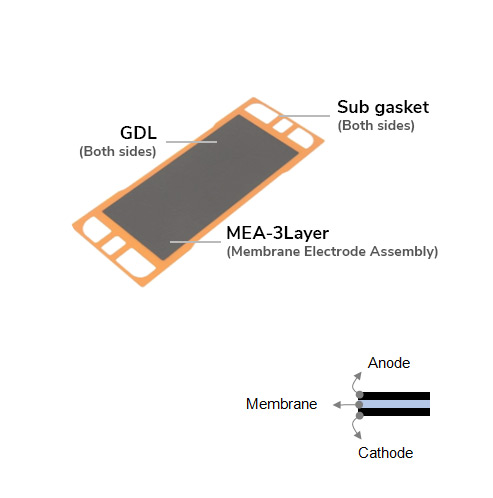

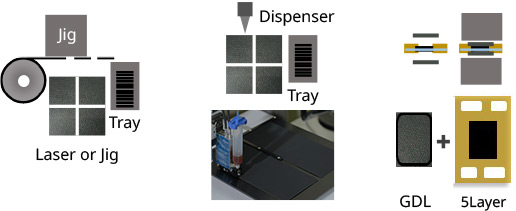

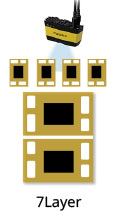

Fuel Cell 7-Layer MEA Structure

Structure where Sub-gasket and GDL are bonded to both sides of the MEA.

Sub-Gasket

Excellent adhesion and durability through adhesive development tailored to fuel cell operating environments.

Adhesive

1. Material: Modified Phenol Epoxy & Rubber

- Designed for strong durability in fuel cell operating environments (acid resistance, moisture resistance, heat resistance, high rigidity, adhesive retention).

- Productivity improvement during processing by adopting curable epoxy (improves leakage issues caused by hardener damage even during impact).

- Designed with rubber to prevent adhesive damage in vibrating environments.

2. Customizable for optimal equipment conditions.

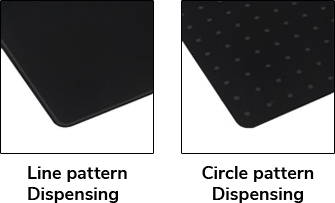

GDL Bond

Excellent adhesion and durability through adhesive development tailored to fuel cell operating environments.

- Hydrophobic Material

- Excellent Printability

- High Adhesion

- Quick Curing Time

- Competitively Low Cost

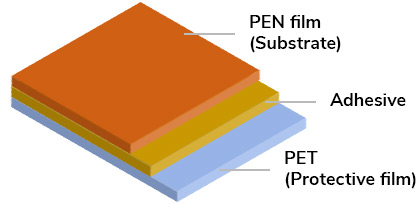

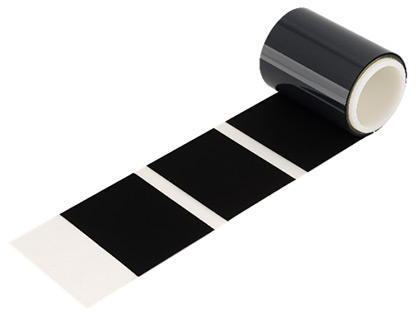

Electrode-Type Film

Excellent coating and no binder slippage for improved electrode performance.

1. Material: Adhesive PET Film

- Introduces an adhesive layer for ease of attachment and detachment. Implements precise pattern coating for R2R transfer processes.

2. Advantages: Electrode-specific film is suitable for automated processes.

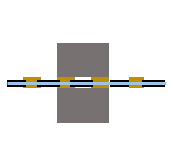

MEA Automation Process Technology

Development and Patenting of R2R automation equipment process technology

| 1. Electrode Slurry | 2. Coating Process (Electrode) | 3. Layer | 4. Layer | 5. Cutting |

|

|

|

|

|

|

|

|

|

|

| 6. GDL Bonding & 7Layer Lami | 7. Inspection |

|

|

Key Partners

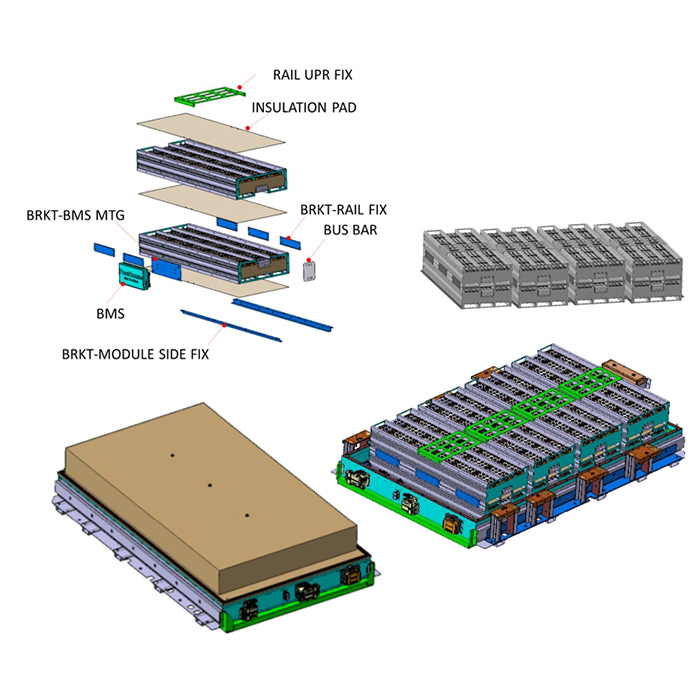

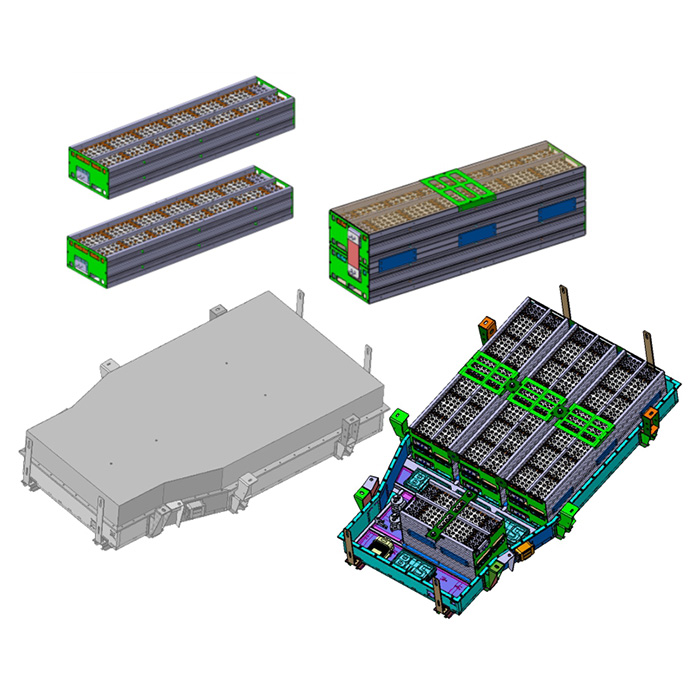

Battery Pack

A unit made by combining multiple battery cells into one, designed to protect against physical shocks from the external environment and capable of performing specific functions. It consists of battery cells, modules, and packs. Equipped with various control and protection systems such as BMS (Battery Management System) and thermal management system for completion.

Importance

“The importance of a battery pack that can improve the performance of an electric vehicle is increasing. Unlike internal combustion engine vehicles, electric vehicles use batteries as power sources, making the battery pack the most crucial component in an electric vehicle, as the vehicle’s performance depends on the performance of the battery pack.”

Functions

By Cell Type: Phosphate, Lithium-Ion, Lithium Polymer

By Cell Form: Cylindrical, Prismatic, Pouch

Custom design and manufacturing with a primary focus on safety

High capacity, high density

Implementation of a Long Life Cycle

DBPDV3-X180

| Category | Contents | Notes | |||

|---|---|---|---|---|---|

| Cell | LGES INR 21700 M50L | ||||

| Nominal Voltage | 324.72V | 88s | |||

| Energy Capacity | 177.48Ah | 36p | |||

| Capacity | 57.6kWh | Cell : 18.2Wh | |||

| Voltage Range | 220 ~ 360.8V | Cell : 2.5 ~ 4.1V | |||

| Charging Method | CC/CV | ||||

| Charging Current | 120A [max] | ||||

| Discharge Current | 180A [max] | ||||

| Temperature | Operation | Charge 0 ~ 45°C / Discharge -20 ~ 55°C | |||

| Storage | 1 year -20 ~ 25°C | ||||

| Size | 1597 x 1038 x 238 | LWH (mm) | |||

| Weight | 340kg | ||||

DBPDV-X130

| Category | Contents | Notes | |||

|---|---|---|---|---|---|

| Cell | LGES INR 21700 M50L | ||||

| Nominal Voltage | 332V | 90s | |||

| Energy Capacity | 128.7Ah | 26p | |||

| Capacity | 42.7kWh | Cell : 18.2Wh | |||

| Voltage Range | 300 ~ 369V | Cell : 2.5 ~ 4.1V | |||

| Charging Method | CC/CV | ||||

| Charging Current | 85A [max] | ||||

| Discharge Current | 108A [max] | ||||

| Temperature | Operation | Charge 0 ~ 45°C / Discharge -20 ~ 55°C | |||

| Storage | 1 year -20 ~ 25°C | ||||

| Kích thước | 1655 x 972 x 272 | LWH (mm) | |||

| Weight | 280kg | ||||

DBPVT-X90

| Category | Contents | Notes | |||

|---|---|---|---|---|---|

| Cell | LGES INR 21700 M50L | ||||

| Nominal Voltage | 14s18p | 90s | |||

| Energy Capacity | 51.66V | 14s | |||

| Capacity | 85.85Ah | 18p | |||

| Voltage Range | 4.43kWh | Cell : 18.2Wh | |||

| Charging Method | CC/CV | ||||

| Temperature | Operation | Charge 0 ~ 45°C / Discharge -20 ~ 55°C | |||

| Storage | 1 year -20 ~ 25°C | ||||

| Size | 350 x 462 x 185 | WDH (mm) | |||

| Weight | 35kg | ||||

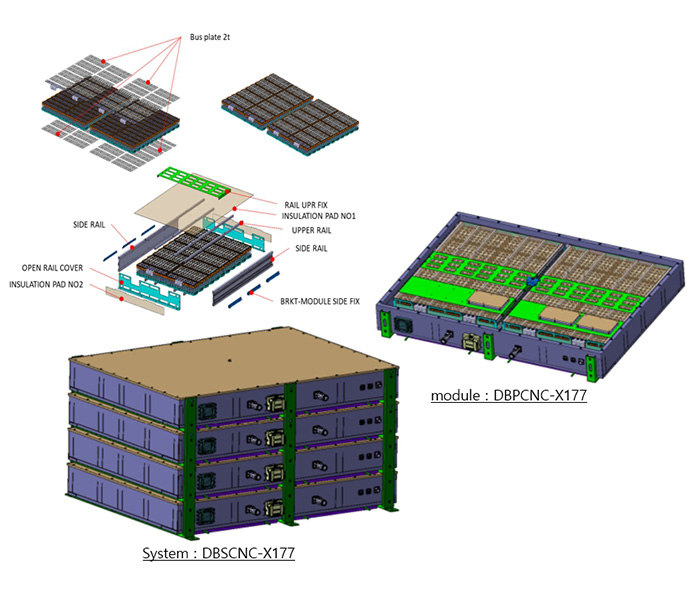

DBPCNC-X177 / DBSCNC-X177

| Category | Contents | Notes | |||

|---|---|---|---|---|---|

| Cell | LGES INR 21700 M50L | ||||

| Nominal Voltage | 44s36p | 11s36p x 4ea | |||

| Energy Capacity | 162.36V | 44s | |||

| Capacity | 177.55Ah | 36p | |||

| Voltage Range | 28.82kWh | Cell : 18.2Wh | |||

| Charging Method | CC/CV | ||||

| Temperature | Operation | Charge 0 ~ 45°C / Discharge -20 ~ 55°C | |||

| Storage | 1 year -20 ~ 25°C | ||||

| Size | 1287 x 987 x 175 | WDH (mm) | |||

| Weight | 190kg | ±2kg | |||

DBPSS-NX12

| Category | Contents | ||

|---|---|---|---|

| Cell | SAMSUNG SDI INR 21700-40T | ||

| Configuration | 88S3P(264 Cell) | ||

| Nominal Voltage | 316.8V | ||

| Nominal Capacity | 12Ah | ||

| SOC 90% Charge (@25℃) | Charging Voltage | 360.8V | |

| Operating Voltage | 289V ~ 360.8V | ||

| Capacity | 10Ah | ||

| Standard Charging Current | 3A | ||

| Maximum Charging Current | 5A | ||

| Continuous Discharge Current | 12A | ||

| Instantaneous Discharge -1 (15seconds) | 24A | ||

| Instantaneous Discharge -2 (5seconds) | 36A | ||

| Weight | about 32kg | ||